Floor Covering

Laying marble, granite, stone and other flooring

99 - 406 BGN

Lining of interior spaces with marble

99 - 406 BGN

Floor grouting

5 - 27 BGN

Corner grouting

5 - 27 BGN

Making screeds

26 - 118 BGN

Installation of laminate flooring

23 - 203 BGN

Installation of cork parquet

23 - 152 BGN

Installation of moldings

18 - 74 BGN

Installation of PVC skirting boards with a cable channel

18 - 85 BGN

Installation of PVC floor coverings

38 - 254 BGN

Installation of linoleum

38 - 254 BGN

Installation of heterogeneous vinyl flooring

38 - 254 BGN

Installation of homogeneous vinyl flooring

38 - 254 BGN

Installation of carpets and carpeted flooring

23 - 169 BGN

Installation of indoor sports flooring

38 - 272 BGN

Installation of outdoor sports flooring

38 - 272 BGN

Installation of shock-absorbing flooring for children's playgrounds

38 - 272 BGN

Installation of industrial flooring (Epoxy floors)

46 - 306 BGN

Laying of polished concrete

30 - 152 BGN

Laying of stamped concrete

46 - 272 BGN

Installation of electrically conductive flooring

38 - 272 BGN

Installation of floor insulation

30 - 136 BGN

Which type of flooring is right for your facility?

The choice is decided by load, hygiene requirements, acoustics, humidity and budget. For homes, comfort and acoustics are a priority, and for offices - wear resistance and easy maintenance. For industry - strength, chemical resistance and safety (anti-slip, ESD). We combine the right material with a quality base (screed/leveling), correct joints and skirting boards to get a long life and a clean finish.

Comparison of solutions (material > when/why)

Vinyl (homogeneous/heterogeneous)

Suitable for offices, healthcare and commercial areas. Advantages: durable layer, water resistance, low maintenance. Load classes 31/32/33; wear layer thickness often 0.5-0.7 mm. Good choice for heavy traffic and easy hygiene.

Laminate

Residential and office spaces with low to medium humidity. Look for AC4/AC5 class and suitable acoustic underlay. Not for wet areas. Flat base is critical.

Carpet (roll/tiles)

Offices, hotels, areas with acoustic requirements. Pros: comfort, noise absorption. Cons: requires regular cleaning.

Epoxy/industrial floors

Warehouses, factories, garages. High chemical resistance and load. Pressure often > 70 MPa depending on the system. Antistatic/ESD options available.

Electrically conductive flooring (ESD)

Electronics/medical environments. Static electricity control according to IEC 61340. Installed with copper tape and conductive adhesive.

Sports flooring for halls and playgrounds (indoor/outdoor)

Criteria: shock absorption, adhesion (R9-R11), rebound, UV resistance. For playgrounds - shock absorption and HIC according to EN 1177.

Linoleum / PVC coatings

Public buildings, schools, healthcare facilities. Ecological solutions (linoleum), good wear resistance (PVC). Easy maintenance.

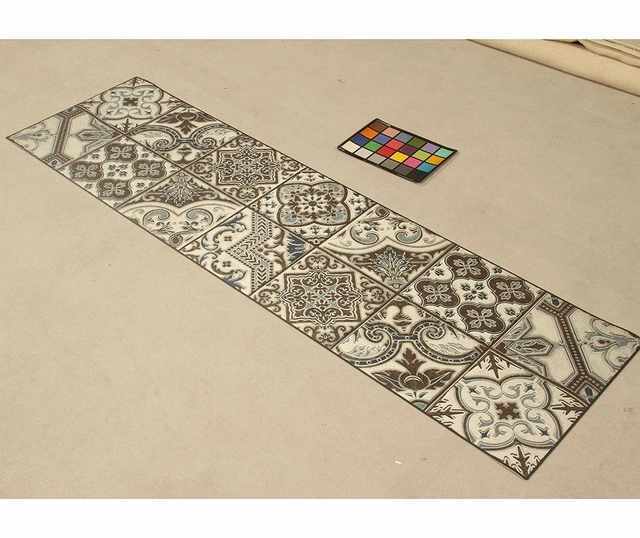

Stone (marble/granite/stone)

Presentative interiors and areas with high wear resistance. Long-lasting, but requires proper grouting and impregnation.

Concrete (polished/stamped)

Parking lots, industrial and outdoor areas. Polished - smooth and durable. Stamped - decorative relief and color. Thickness, reinforcement and joints are important.

Cork

Housing with a focus on thermal/noise comfort. Natural material, needs appropriate protection against moisture.

The base is 50% of the result

A good floor starts with a strong and even base. We measure the moisture content of the screed, check the evenness, observe the drying time. If necessary, we pour a leveling screed, add vapor barrier, acoustic pads and expansion joints. The choice of adhesive/primer takes into account the material and conditions (underfloor heating, humidity, load).

Floor and flooring services

- Installation of heterogeneous vinyl flooring - laying with precise cutting, welding of joints and skirting boards for a hygienic finish.

- Installation of floor insulation - heat and sound insulation pads, proper vapor barrier over damp substrates.

- Installation of electrically conductive flooring - construction of an ESD system with conductive adhesives and copper tapes, resistance control.

- Installation of stamped concrete - reinforcement, relief matrices and coloring, sealing against abrasion and water.

- Installation of polished concrete - leveling, grinding, impregnation, planar cutting of joints for crack control.

- Installation of industrial flooring (epoxy floors) - multi-layer systems, quartz sand for anti-slip, extremely wear-resistant coating.

- Installation of shock-absorbing flooring for playgrounds - slabs/cast rubber with thickness according to the height of the fall, seamless finish.

- Installation of outdoor sports flooring - UV stable systems, drainage and markings, optimal traction.

- Installation of indoor sports flooring - elastic surfaces with shock absorption and rebound control.

- Installation of carpets and carpet flooring - stretching/gluing, edge processing and transition strips.

- Installation of homogeneous vinyl flooring - seamless appearance with welding, easy maintenance at high load.

- Laying of flooring made of marble, granite, stone and others - calibration, cutting, gluing and grouting, impregnation.

- Installation of linoleum - eco-friendly composition, natural pigments, welding of joints for hygiene.

- Installation of PVC floor coverings - rolls/plates, durable layer and easy cleaning.

- Installation of PVC skirting boards with cable channel - clean installations and hidden cables, corner elements for a finished look.

- Installation of floor skirting boards - precise jointing, internal/external corners, visual finishing.

- Installation of cork parquet - floating/glued, natural comfort, protection against moisture.

- Installation of laminate parquet - underlay, expansion joints, precise cutting around frames and pipes.

- Making screeds - cement/self-leveling, thickness, flatness and humidity control.

- Corner grouting - elastic sealants in critical transitions to prevent cracks.

- Floor grouting - selection of grout according to material/width, clean finish and easy maintenance.

- Marble tiling of interior spaces - stenciling, precise gluing, polishing.

Practical selection criteria

- Load and class: traffic, furniture on castors, pallet trucks.

- Moisture/maintenance: kitchens, bathrooms, outdoor areas.

- Safety: anti-slip (R9–R11), ESD, shock absorption.

- Acoustics/Comfort: residential, educational and office environments.

- Budget and time: materials, substrate preparation, express installation.