Plumbing services

Dismantling of old pipes

12 - 103 BGN

Installation and sealing of a water meter

122 - 1017 BGN

Installation of a shower faucet

122 - 847 BGN

Replacement of risers, cranes

46 - 221 BGN

Replacement or repair of a plumbing installation

228 - 1695 BGN

Installation of new pipes

12 - 118 BGN

Installation of pipe insulation

5 - 25 BGN

Construction of a water metering unit with a shut-off valve and a water meter

152 - 1017 BGN

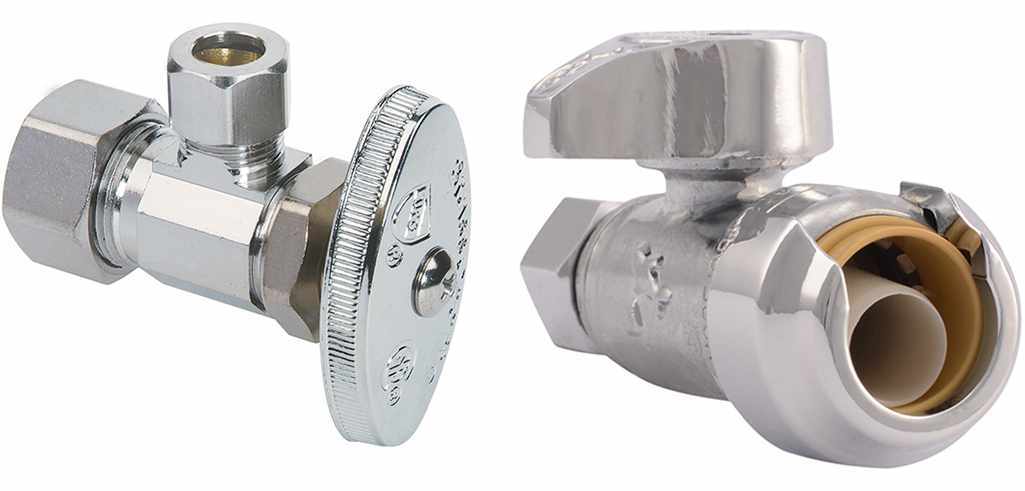

Replacing a shut-off valve

38 - 203 BGN

emergency removal of leaks from radiators and pipelines

200 BGN

Installation of a sink siphon

46 - 306 BGN

Installation of a porcelain sink

122 - 847 BGN

Installation of a plastic cistern

46 - 272 BGN

Installation of Toilet

182 - 1017 BGN

Installation of a built-in structure (toilet)

228 - 1356 BGN

Moving radiators

152 - 508 BGN

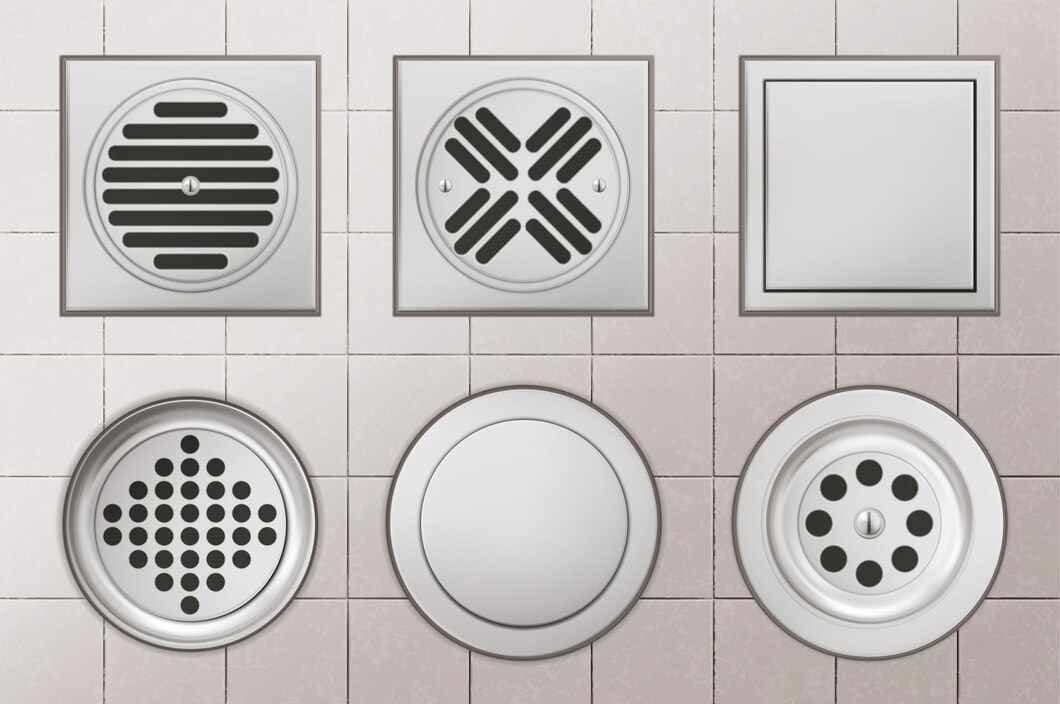

Unclogging a floor siphon in a bathroom

61 - 339 BGN

Unclogging a sink siphon in a kitchen or bathroom

61 - 272 BGN

Unclogging a toilet

61 - 339 BGN

Unclogging an external sewer

228 - 1017 BGN

Emergency Plumbing Services

200 BGN

Emergency Unblocking

200 BGN

Unclogging a channel

76 - 508 BGN

Sink installation

61 - 508 BGN

Soft link replacement

30 - 203 BGN

Installation of a shower

304 - 1356 BGN

Leak removal

228 - 847 BGN

Construction of a new sewer

76 - 406 BGN

Sphere installation of start taps

61 - 339 BGN

Faucet installation

76 - 406 BGN

Case study for plumbing services

In the morning, the bathroom smells like a drain. The sink drains slowly, and moisture appears under the water heater. The inspection shows three different problems: a clogged floor siphon, a worn soft connection on the mixer, and a weak slope in a section of the sewer. The solution requires quick diagnostics, correct unclogging, replacement of elements, and correction of slopes to prevent new accidents.

Diagnostics: how we find the source of the problem

We work according to a clear protocol: visual inspection → tracing → instrumental checks. We use a sewer camera for internal inspection of the pipes, water pressure tests for plumbing (typically 6 bar for testing new PPR sections) and a smoke test in case of suspicion of false siphons/missing water plugs. For proper operation, we check the slopes of the horizontal discharge pipes (guideline 2-3% depending on the configuration) and the seals of all connections. For radiators and mixers, we measure the flow rate and check the stopcocks.

Solutions

Quick recovery

- Unblocking a sink siphon in a kitchen or bathroom and unblocking a floor siphon with professional spirals and hydrojet.

- Replacing a soft connection on a mixer or toilet cistern, replacing a stopcock for safe stopping during future repairs.

- Cleaning siphons and inspections, tightening connections, checking for micro-leaks.

Replacing or correcting sections

- Dismantling old pipes with corrosion/deposits and installing new ones pipes of appropriate diameter.

- Construction of new sewers where old routes are irregular; correction of slopes for sustainable drainage.

- Replacement and repair of plumbing installation in bathroom/kitchen, including installation of pipe insulation to protect against condensation and noise.

- Replacement of risers and taps when there is frequent condensation, rust or low flow.

Complex repairs and equipment

- Unblocking of external sewers and main lines; locating settlements/bends with a camera.

- Moving radiators and reconfiguring water circuits during room renovations.

- Constructing a water meter unit with accessibility for control and installing and sealing a water meter according to requirements.

- Installing ball valves at key points for easy shutdown of individual circuits.

Installation services (sanitary and bathroom) — overview by elements

- Installation of a built-in structure: correct leveling, soundproofing pads, hermetic connection to the duct.

- Installation of a monobloc / bidet: stable fixation, seals, leak test.

- Installation of a plastic cistern and adjustment of the filling/draining mechanism for optimal flow rate.

- Installation of a porcelain sink and installation of a sink siphon: correct choice of siphons (bottle/pipe) according to the space.

- Installation of a mixer and installation of a shower faucet: correct eccentrics, leveling, sealing, check of flow rate/temperature.

- Installation of a shower cabin: leveling of trough/threshold, silicone seals, leak test at start-up.

- Sink installation (standardized installation for different materials and cabinets).

Leak removal and sewer problems

- Leak removal: localization, replacement of seal or section, repeated pressure test.

- Sewer unblocking and toilet unblocking: mechanical/hydrojet, avoid aggressive chemicals because they damage seals and pipes.

- External sewer unblocking: cleaning roots/debris, restoring inspection holes for future maintenance.

When to act immediately

- Persistent odor in the duct despite ventilation.

- Moisture/drops on ceilings/walls, stains around siphons.

- A sharp drop in flow rate or noises when starting.

- Frequent blockages at the same point.

- After bathroom renovation — lack of pressure test or documentation.

Installations and finishing touches that make a big difference

- Installation of a water meter and monitoring of consumption for early detection of leaks.

- Installation of pipe insulation in cold/hot water for comfort and economy.

- Installation of new pipes with appropriate diameter and materials according to the application (PPR/PEX/copper).

- Construction of new sewage with revisions to key points for quick access.

- Installation of ball valves on branches to sinks, boilers, mixers — facilitate future maintenance.

Safety and efficiency benefits

Correct slopes and diameters prevent water backflow and noise. High-quality shut-off elements minimize the risk of accidents. Pressure tests and visual inspection with a camera ensure that hidden sections are properly installed. The result is fewer emergency repairs, clean work and trouble-free operation in the long term.